Article & News

What Is Moulded Plywood? Uses, Advantages & Buying Guide

Unlike ordinary plywood, moulded plywood is not carved into shape. It has a form. Instead of flat boards, thin layers of wood are pressed into curves with heat, pressure, and moulds. This is what gives moulded plywood its rounded shapes and easy bends. In this article, we’ll explain how moulded

Veneer Sheets: Types, Uses, Benefits & Buying Guide

Many individuals mistakenly take veneer sheets similar to laminate. We see this frequently when people are selecting furniture or finishes for doors. From a distance, the two can appear quite alike. That’s where the misunderstanding begins. However, veneer and laminate are not identical. One consists of real wood on the

Blockboard Beds: Benefits, Features & Why They’re Perfect for Your Bedroom

When it comes to buying a bed, design is usually the most crucial factor. The material used to create the bed, however, has the greatest impact on its comfort, stability, and longevity. This is why many modern houses now choose engineered wood beds. They provide an excellent blend of strength

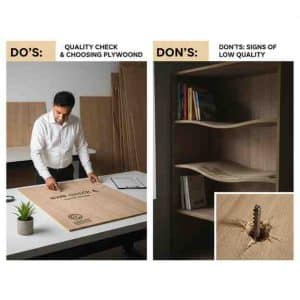

Do’s and Don’ts of Choosing Plywood: A Complete Guide for Smart Buyers

Purchasing plywood may seem easy, but when you’re standing in front of stacked sheets, everyone around you has a different perspective. While one person discusses grades, another promotes products, and still another remarks, “This is good enough.” Many customers choose plywood for its name or price, only to discover later

Which Plywood Should You Use for Every Area of Your House

Selecting the “best” plywood for a house doesn’t mean using it everywhere. Every room serves a different purpose. As for example, the kitchen deals with everyday use, heat, and steam. Bedrooms receive very little moisture and remain generally dry. In contrast, bathrooms are nearly always exposed to moist circumstances. As

Which Plywood Should You Use? Expert Tips for Perfect Material Match

If you’ve ever gone to buy plywood and felt unsure about what to pick, you’re definitely not alone. One dealer suggests one grade, another pushes something else, and suddenly there are too many options to make sense of. Different plywood types, different grades, and different uses—it’s easy to feel confused,