Article & News

How to Determine the Quality of Plywood: 5 Proven Steps (2026 Guide)

Walk into a plywood shop, and most sheets look the same. Same size. Same colour. Same claims. But once that plywood is used in a kitchen, wardrobe, or bed, the difference becomes clear. Some boards stay strong. Others start showing surface issues or begin to bend and swell within a

Different Plyboard Sizes Explained: Standard Length, Width & Thickness (2026 Guide)

When purchasing plywood, consumers typically prioritize either the brand or the cost. Size is frequently disregarded. That’s when issues start. Choosing the wrong plywood size or thickness is not a major concern initially, but it can lead to weak shelves, sagging doors, unwanted joints, or wasted material later. Even high-quality

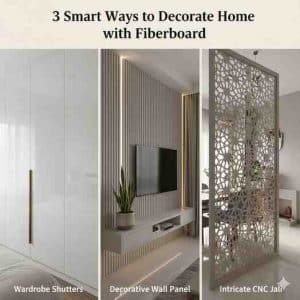

3 Incredible Ways to Embellish Your Home with Fiberboard Partitions

Although open floor plans are attractive, they are difficult to live in. When everything starts to blend, smart zoning helps each space feel separate—without making the home feel tight or boxed in. Partitions are useful in this situation. Without requiring permanent construction, partitions help define spaces like living, dining, and

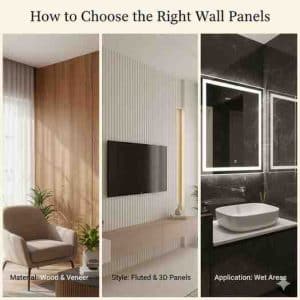

Buying Guide: How to Choose the Right Wall Panels

These days, wall panels are used for much more than merely decorating walls. They enhance soundproofing, control moisture, shield surfaces, and strengthen a room’s structure. That is why most homeowners are using wall panels instead of just paint or wallpaper. But trends and décor talk are not the focus of

What are the best wall partition ideas for living room interiors?

Modern living rooms do much more than just entertain guests. They can be used as family rooms, workspaces, and even dining areas. This is why many homes want a way to divide space without renovations or the wall construction. This is where partition walls come in. They contribute structure, privacy,

Benefits of Using Natural Plywood for Furniture and Interiors

Most of the time, when people ask what natural plywood is, they don’t inquire how it’s manufactured. What consumers want to know is if it looks natural, feels safe to use, and integrates well with typical furniture. Natural finishes and safer materials are becoming increasingly popular in homes, particularly for