Introduction

Plywood is a staple material in the world of construction and woodworking, known for its versatility, strength, and cost-effectiveness. However, not all plywood is created equal. Different types of plywood are designed to meet specific needs and applications, each with unique characteristics and benefits. In this blog, we will explore the various types of plywood and their uses, helping you choose the right kind for your next project.

Understanding Plywood

Plywood is a manufactured wood product made by glueing together thin layers, or “plies,” of wood veneer. These layers are stacked in alternating grain patterns to enhance strength and reduce the risk of warping. The result is a strong, stable, and versatile panel suitable for a wide range of applications.

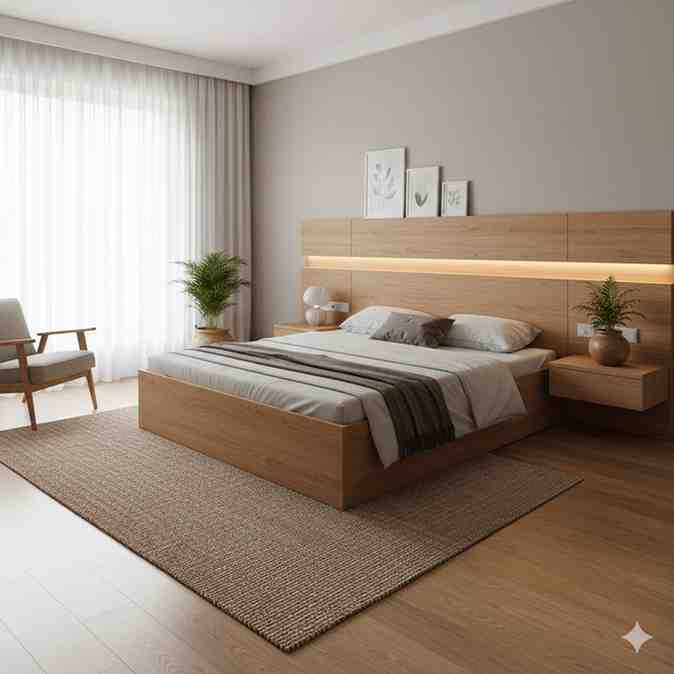

Transform your interiors with high-quality plywood designed for elegance and performance.

Types of Plywood

Softwood Plywood

Made from softwood species such as pine, fir, or spruce, softwood plywood is widely used in construction and industrial applications.

Uses:

- Sheathing: Used in walls, roofs, and floors for structural support.

- Subflooring: Provides a stable base for various types of flooring.

- Packaging: Ideal for crates, pallets, and boxes due to its durability.

Hardwood Plywood

Constructed from hardwood species like oak, maple, and birch, hardwood plywood is known for its strength, stability, and aesthetic appeal.

Uses:

- Cabinetry: Preferred for making kitchen cabinets and furniture.

- Furniture: Commonly used in tables, chairs, and other fine furniture pieces.

- Panelling: Used for decorative wall panels due to its attractive finish.

Marine Plywood

Engineered for water resistance, marine plywood uses high-quality veneers and waterproof adhesives, making it suitable for wet environments.

Uses:

- Boat Building: Essential for constructing hulls, decks, and other boat parts.

- Outdoor Structures: Ideal for docks, piers, and other structures exposed to water.

- Bathrooms and Kitchens: Used in areas prone to moisture, such as cabinets and countertops.

Exterior Plywood

Designed to withstand outdoor conditions, exterior plywood is treated with water-resistant adhesives and finishes.

Uses:

- Siding: Used for exterior walls and facades.

- Roofing: Provides a durable underlayment for various roofing materials.

- Outdoor Furniture: Suitable for garden furniture and other outdoor applications.

Interior Plywood

Not intended for exposure to moisture, interior plywood is used primarily indoors.

Uses:

- Ceilings and Walls: Ideal for panelling and decorative finishes.

- Furniture: Commonly used in non-load-bearing furniture pieces.

- Partitions: Used to create interior partitions and dividers.

Structural Plywood

Known for its high strength and load-bearing capacity, structural plywood is used in critical structural applications.

Uses:

- Framing: Essential for constructing frames and supports in buildings.

- Bracing: Reinforces walls and roofs.

- Flooring: Used as a base for various types of flooring in both residential and commercial buildings.

Flexible Plywood

Manufactured with thin veneers to allow bending and shaping, flexible plywood is used in applications requiring curves and intricate shapes.

Uses:

- Furniture Design: Ideal for creating curved furniture and decorative pieces.

- Architectural Elements: Used for curved walls and ceilings in modern architecture.

- Set Design: Commonly used in theatre and film set construction for creating elaborate shapes and designs.

Choosing the Right Plywood

When selecting plywood for your project, consider the following factors:

- Environment: Determine whether the plywood will be exposed to moisture or used outdoors.

- Load-Bearing Requirements: Choose structural plywood for applications requiring high strength and support.

- Aesthetic Considerations: For visible applications like furniture and panelling, opt for hardwood plywood with a high-quality finish.

- Flexibility Needs: Use flexible plywood for projects involving curves and complex shapes.

Know more about choosing the right plywood dimensions for your next project and ensure durability that lasts.

Conclusion

Plywood is an incredibly versatile material, with various types tailored to meet specific needs and applications. By understanding the differences between softwood, hardwood, marine, exterior, interior, structural, and flexible plywood, you can make informed decisions for your projects, ensuring durability, strength, and aesthetic appeal. Whether you’re building a boat, crafting fine furniture, or constructing a new home, there’s a type of plywood perfectly suited for the job.

Transform your spaces with Wigwam Ply, crafted for elegance, strength, and long-term value.

FAQS

- Which type of plywood is best for furniture?

Hardwood plywood is generally preferred for furniture due to its strength, stability, and attractive finish. It is commonly used in cabinets, tables, chairs, and other fine furniture pieces.

- Can marine plywood be used indoors?

Yes. While marine plywood is designed for wet environments, it can also be used indoors in areas prone to moisture, such as kitchens, bathrooms, or basements.

- What is the difference between exterior and marine plywood?

Exterior plywood is treated to resist weather conditions, while marine plywood uses high-quality veneers and waterproof adhesives to withstand constant water exposure, making it more durable in wet environments.

- Is flexible plywood strong enough for structural purposes?

Flexible plywood is designed for bending and shaping, not heavy load-bearing. It is best suited for decorative or architectural purposes rather than structural applications.

- How do I choose the right plywood for my project?

Consider the environment (indoor or outdoor use), load-bearing requirements, aesthetic needs, and whether you require flexibility for curves. Match the plywood type to the specific conditions of your project for the best results.