Unlike ordinary plywood, moulded plywood is not carved into shape. It has a form.

Instead of flat boards, thin layers of wood are pressed into curves with heat, pressure, and moulds. This is what gives moulded plywood its rounded shapes and easy bends.

In this article, we’ll explain how moulded plywood is created, where it’s most typically used, and whether it’s stronger than conventional plywood. If you’ve ever wondered how wood retains its shape, this is for you.

What Is Moulded Plywood and How Is It Made

Plywood that is moulded into curves rather than remaining flat is known as moulded plywood. If you’re wondering what moulded plywood is used for or how it is created, the answer is easy.

Thin layers of wood are stacked with glue and placed into a mould. By applying pressure and heat, the layers become softer and are compelled to conform to the mould’s shape. The plywood maintains that shape after cooling.

Moulded plywood differs greatly from flat plywood boards, which are cut and assembled afterwards, due to this technique. The shape is integrated into the material itself.

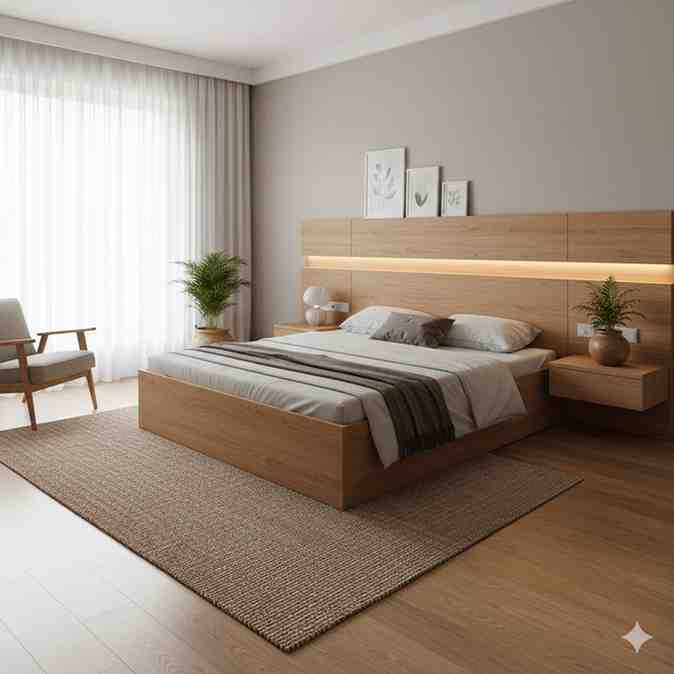

Moulded plywood is typically utilized in situations where comfort, curves, and smooth edges are more important than flat surfaces.

Common Uses of Moulded Plywood

The majority of moulded plywood uses are for furniture that requires comfort and shape. It is commonly found in furniture pieces where flat plywood would not function well, particularly where curves enhance use or design.

Common uses include:

- Moulded plywood furniture with curved panels.

- Moulded plywood chairs and seating shells.

- Task chairs and visitor seating are examples of office furniture.

- Pieces of modular furniture that are circular or flow.

Moulded plywood can usually be found where you see soft bends rather than abrupt gaps.

You can also check out maintenance tips for water-resistant plywood for its lifespan. Moulded Plywood Chairs and Furniture Components

Moulded plywood works particularly well for chairs, which is why they are so popular. Chairs must be able to support weight, movement, and extended use. Curved plywood distributes stress more evenly than flat panels.

Common moulded plywood chair items are: shells for seats, the backrests, and the armrests

The body-support form of plywood enhances comfort while maintaining its strength. Additionally, it allows designers greater latitude to produce smooth, flowing shapes without the need for additional joints.

Moulded Plywood vs Bent Plywood

Moulded plywood and bent plywood are not the same thing, even though people often confuse them.

Usually, bent plywood is made by forcing flat plywood into a curved shape during the production process. In contrast, moulds are used to form moulded plywood during production.

Moulded plywood provides better shape control and a smoother finish. The contours appear more uniform and tidy. The fact that the layers are created together rather than under tension later makes it generally stronger.

Bent plywood can be used for smaller curves and can be less expensive. When long-term durability, comfort, and accuracy are required in the design, moulded plywood is the superior option.

Is Moulded Plywood Strong and Customizable?

A lot of people wonder if moulded plywood is more durable than ordinary plywood. In most shaped applications, the answer is yes.

By efficiently distributing weight, the curved shape increases strength for everyday use. Moulded plywood works effectively in sitting and load-bearing furniture because of this.

It is also possible to customize moulded plywood. Various sizes, forms, and finishes can be achieved based on the mould and design specifications.

However, there are boundaries, so other materials can be required for extremely steep curves or large structural loads. Moulded plywood performs best in situations where shape and comfort are important.

Moulded Plywood Price and What Affects It

Unlike conventional plywood, the price of moulded plywood is typically determined per piece rather than per sheet.

The cost of moulded plywood per piece is determined by:

- Complexity of design

- The thickness and quantity of layers

- Type of finish

- Custom or readymade manufacturing

The cost of custom moulds is higher, particularly for small volumes. The cost of ready-made designs is affordable.

Even though moulded plywood is more expensive initially, it eliminates the need for additional joints and fittings, increasing value over time.

Check out this complete guide for choosing plywood to make an informed choice.

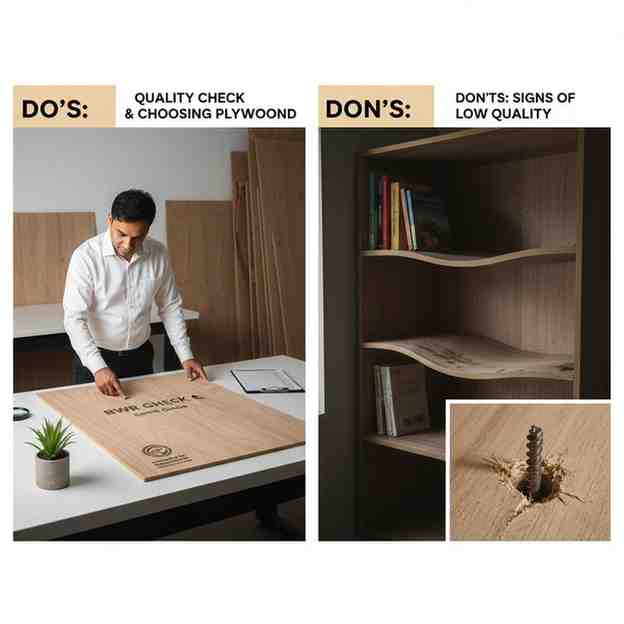

Things to Check Before Buying Moulded Plywood

Before purchasing moulded plywood, consider where and how you will utilize it.

Let’s start with the expected usage. Chairs, office furniture, and modular pieces all have varying strength and comfort requirements. Check the thickness, number of layers, and surface polish to ensure they are appropriate for the intended use.

Next, consider whether you require a custom shape or if a pre-made item will suffice. Despite its superior appearance, custom-moulded plywood is typically more expensive.

Moulded plywood makes sense for design, comfort, and smooth curves. Ordinary plywood is often a more obvious option for flat, uncomplicated furniture. If you’re not sure which plywood or thickness is best for your needs, Wigwam Ply can help select the proper material so your furniture performs well and lasts longer.

FAQs

1. What is moulded plywood?

Moulded plywood is basically plywood that’s given a shape instead of being kept flat. Instead of cutting boards and joining them, the wood layers are pressed into curves. That’s why you see it in those smooth, curved chairs.

2. How is moulded plywood manufactured?

It’s made by stacking thin wood layers with glue and placing them inside a mould. Heat and pressure are applied so the layers soften and take the shape of the mould. Once it cools, the shape stays. So the curve isn’t forced later. It’s built into the material from the start.

3. What are the common uses of moulded plywood?

You’ll mostly see moulded plywood in furniture that has curves. Chairs are the most common example. It’s also used in backrests, seating shells, and some modular furniture parts.

Anywhere you see smooth bends without heavy joints, moulded plywood is probably behind it.

4. Is moulded plywood stronger than flat plywood?

For curved parts like chairs, yes, it often feels stronger because the curve spreads weight better. But for flat surfaces like shelves, regular plywood works just fine.

So it’s not about stronger or weaker in general — it depends on the job.

5. What furniture items use moulded plywood components?

Dining chairs, office chairs, study chairs, auditorium seats — these often use moulded plywood for the seat and back part. It’s chosen mainly for shape and comfort.

6. What is the difference between moulded plywood and bent plywood?

People mix these up a lot. Moulded plywood is shaped while it’s being made, while bent plywood is usually flat plywood that’s later bent into shape.

Moulded plywood gives cleaner curves and better consistency. Bent plywood works for simpler designs.

7. Can moulded plywood be customized in shape and size?

Yes, but there’s a catch. Since it’s made using moulds, you need a specific mould for each design. That means custom shapes are possible, but they can cost more.

For large production, it makes sense. For small projects, maybe not.

8. Is moulded plywood suitable for office and commercial furniture?

Yes, it’s actually quite common in offices. Many office chairs use moulded plywood inside. It handles regular use well when made properly. But quality matters– thickness and bonding should be right.

9. What thickness is used for moulded plywood?

There isn’t one fixed thickness. It depends on how much load the piece needs to handle. Chairs usually need thicker layers. Decorative panels can be thinner, but the usage decides the thickness.

10. How durable is moulded plywood furniture?

If made properly, it can last for years. The curved structure helps with strength. But durability depends on:

- Quality of layers

- Adhesive used

- Thickness

- Finish

Like most materials, it performs well when used properly.