Walk into a plywood shop, and most sheets look the same. Same size. Same colour. Same claims.

But once that plywood is used in a kitchen, wardrobe, or bed, the difference becomes clear. Some boards stay strong. Others start showing surface issues or begin to bend and swell within a short time. This usually happens because the quality wasn’t checked properly at the time of purchase.

If you know how to determine the quality of plywood, you can avoid most of these problems.

You don’t need expert tools or technical knowledge. A few basic checks at the shop can reveal how good a board really is.

In this blog, we will share 5 simple steps to follow in 2026 to check plywood quality before buying, so you pick material that lasts long.

Step 1: Check the Plywood Grade and ISI Mark

Check the plywood’s ISI mark first. A sheet should not be trusted if it lacks a clear ISI certification. Plywood is available in a variety of grades for various applications. Some grades function well in dry environments, while others are for kitchens and other moisture-prone areas.

The grade of the plywood must be appropriate for the desired usage. If the marking appears to be uncertain, fading, or missing, skip that sheet, as it can frequently cause problems later.

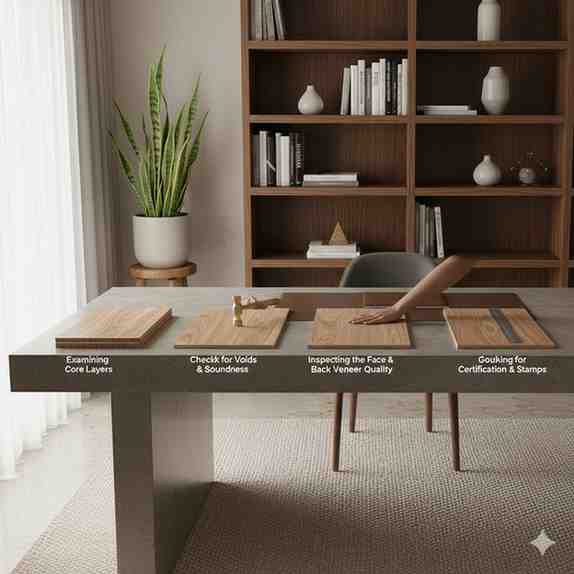

Step 2: Inspect the Core and Layers

Check the plywood’s side edge to verify the layers and core. The sheet should be divided into tidy, uniform layers. If feasible, count the layers of plywood, as more layers tend to provide more strength and stability.

Additionally, keep an eye out for any gaps, overlaps, or uneven layers within the core. A clean and well-packed core is a sign of superior manufacture and usually indicates that the plywood will survive longer aging. A strong core also means better bonding and longer life.

Step 3: Test Adhesive and Bonding Strength

Gently push the edges of plywood with your fingers to test its bonding strength. Instead of feeling flimsy or mushy, the edges should be solid. Examine the layers along the edge closely. If they already appear to be splitting, that’s a red flag.

A good adhesive holds the layers together for years, whereas weak bonding causes peeling, cracking, and damage over time.

Step 4: Check for Moisture and Termite Resistance

Always ask the vendor if the plywood has been treated for termites and moisture. Don’t assume from the sheet alone. Check the edges closely for any rough spots or swelling, as these indicate that the plywood is not very resistant to moisture.

When purchasing plywood for storage units, kitchens, and wardrobes—places where moisture exposure is more frequent—this inspection is particularly crucial.

Read this guide if you’re confused about choosing between plywood and blockboard for your home furniture.

Step 5: Simple Quality Tests Without Cutting

Check plywood using your fingertips. A good-quality sheet gives a firm, solid sound. Generally, a hollow or uneven sound indicates weak places or holes inside.

Check the margins once again. They need to appear straight and firmly packed together. Loose or uneven edges are common indicators of inadequate bonding.

Gently stroke the surface with your hand. There shouldn’t be any lumps or uneven patches.

What to Look for When Buying Plywood

Check if the thickness is consistent across the sheet by running your hand along the edges or checking at different spots. Uneven thickness may cause fitting issues and reduce the overall strength of the furniture.

The surface should have an even, smooth appearance with few spots or filled areas. Regular repairs on a surface often indicate weaker inner layers.

Always pay close attention to the label. Plywood grade, thickness, and certification are examples of information that should be made explicit. Also, take note of how the plywood is stored in the shop, as sheets placed on moist floors or in open places might lose quality before being used.

Steps to Identify Good Plywood for Furniture

Step 1: Align the grade of plywood with its intended use.

The first step when identifying the right plywood for furniture is to choose the appropriate grade for the desired usage. Plywood designed for dry locations may be suitable for beds or tables, but kitchens and wardrobes require more moisture resistance. In many cases, using the wrong grade causes early damage.

Step 2: Consider more than just pricing when selecting plywood.

Cost should never be the only consideration. Cheaper plywood frequently uses worse bonding, treatment, or core quality. In most cases, investing a little extra in higher-quality plywood will prevent future repairs and replacements.

Step 3: Purchase from reputable vendors.

Always buy plywood from reliable vendors. Reliable suppliers stock properly approved materials and store them in a proper place. They can also help you if you have questions about grades or usage.

The Bottom Line:

It is important to know how check the quality of plywood. A few simple checks at the time of purchase can help you avoid bending, swelling, and future repair concerns. High-quality plywood has a longer lifespan, maintains its shape, and is attractive when used regularly. After the furniture is installed, it also provides you with peace of mind.

Wigwam Ply is the reliable option for kitchens, closets, and home furnishings if you’re searching for a dependable solution that strikes a mix between strength, finish, and consistency. Selecting the right plywood today will be beneficial for the long term.

FAQs

1. How do you know plywood is of good quality?

Honestly, you can tell a lot just by looking and feeling it. Check the edges first. If the layers look even and tight, that’s usually a good sign. The surface should feel smooth and firm, not powdery or rough. Always ask where it’s meant to be used—kitchen, wardrobe, or a dry area. Good plywood feels solid, not light or hollow.

2. What’s the best way to check plywood quality?

There’s no single trick, you just have to do a few basic things together. Look at the layers on the side, tap it lightly—it shouldn’t sound empty. Ask for the grade and whether it has ISI certification. If a seller avoids these questions, that itself tells you something.

3. Why is ISI certification important for plywood?

Because it’s one of the few things you can trust without guessing. ISI means the plywood has passed certain strength and bonding tests. Without it, you’re mostly relying on claims. With it, at least there’s a standard backing the product.

4. Can you judge plywood quality without cutting it?

Most of the time, yes, you don’t need to cut it open. Check the edge finish, if the thickness is uniform, and at the surface for bubbles or cracks. Also, ask about the warranty and grade. Cutting is rarely practical when buying anyway.

5. Does thicker plywood always mean better quality?

Not really, thickness helps, but it’s not everything. A thick sheet with poor bonding or gaps inside won’t last. On the other hand, a slightly thinner sheet with good layers and strong glue can perform much better over time.

6. How long does good-quality plywood last?

If you choose the right grade for the right place, good plywood can last 15–20 years, or more. Most problems come because the wrong plywood is used in kitchens or damp areas, not because plywood itself is bad.