🥇India mein pehli baar - ONLY Calibrated Ply, Life-time guarantee ke saath!

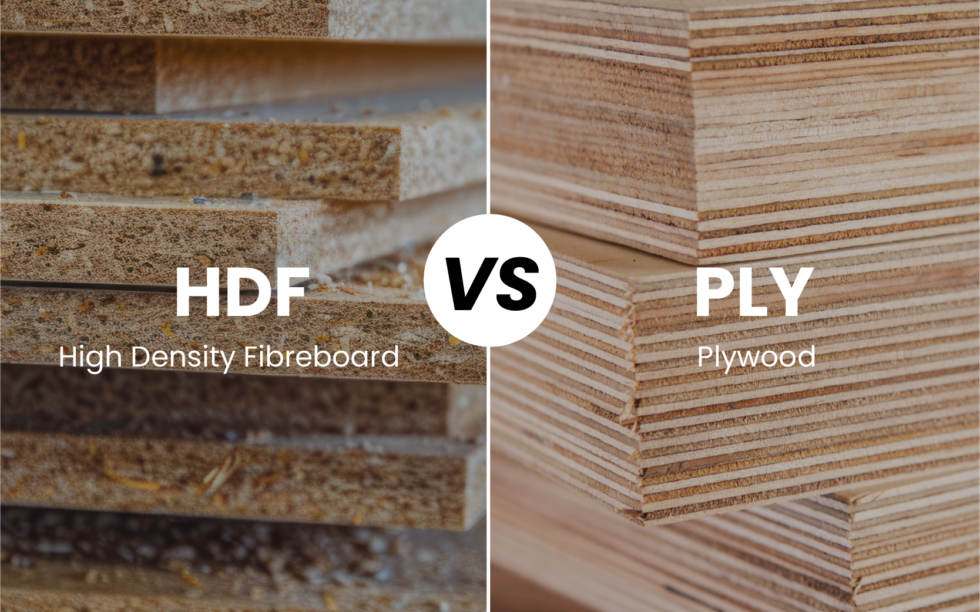

When it comes to decking out our homes, deciding between plywood and HDF/MDF (High-Density Fiberboard) can be tricky. While HDF/MDF might seem like a budget-friendly option, plywood remains the top pick for Indian homes, thanks to its unbeatable strength and versatility. In this article, we’ll break down why plywood should be your number one choice for sprucing up your living space, highlighting the advantages over overhigh-density fiberboard.

Table of Contents

Toggle

MDF stands for Medium Density Fiberboard. It’s a type of engineered wood product made from wood fibres, combined with resin and wax, and formed into panels under high temperature and pressure. MDF is known for its smooth surface, uniform density, and consistency, making it popular in furniture manufacturing, cabinetry, moulding and other applications where a smooth, paintable surface is desired. It’s often used as a substitute for solid wood in various woodworking projects due to its affordability.

HDF stands for High-Density Fiberboard. Similar to MDF, HDF is an engineered wood product made from wood fibres, but it is typically denser and stronger. HDF is produced by compressing wood fibres with adhesive under high pressure, resulting in a dense panel with a smooth surface. HDF is commonly used in applications where strength, durability, and a smooth finish are required, such as laminate flooring, furniture, cabinetry, and decorative wall panels. Due to its high density, HDF is often chosen for applications where impact resistance and structural stability are important.

Plywood is a type of engineered wood product made from thin layers of wood veneer, called plies or layers, that are glued together with the grain of adjacent layers perpendicular to each other. This cross-graining technique gives plywood its strength and stability, making it resistant to cracking, warping, and splitting.

Plywood comes in various grades and thicknesses, and it’s used in a wide range of applications, including construction, furniture manufacturing, cabinetry, flooring, and packaging. Its versatility and strength make it popular in both structural and decorative applications. Plywood can be made from different types of wood, and the choice of wood species can affect its appearance, strength, and cost.

Upgrade your interiors with durable HDF/MDF plywood. Shop now!

Plywood:

Imagine plywood as a stack of sturdy wooden layers glued together. This reliable material stands firm against bending and cracking, making it perfect for crafting all your furniture and home essentials. From sturdy beds to elegant dining tables, plywood has you covered, offering an additional layer of safety with its Fire-Resistant Plywood variant.

HDF/MDF (High-Density Fiberboard):

Now, HDF/MDF is like that smooth-talking friend who’s not exactly built for heavy lifting. Made by pressing wood fibres together, HDF/MDF offers a smooth surface but lacks the strength and durability of plywood.

Picture this: your grandma’s old cupboard, packed to the brim with pots and pans. Plywood can handle that weight like a champ, keeping your furniture sturdy and reliable for years to come.

We all know someone who loves to hang a dozen pictures on their wall. Plywood’s strong grip ensures those hinges stay firmly in place, no matter how many frames they decide to hang. Remember, Wood fibre = Loose hinges, Solid Veneers = Strong built.

Let’s keep it clean! Plywood contains fewer chemicals compared to HDF/MDF, keeping your home free from toxins and your family healthy and happy.

It’s like a tea test for plywood. Dip it in boiling water, and it comes out unscathed. Plywood’s resistance to swelling and warping makes it perfect for areas prone to moisture, like the kitchen and bathroom.

Know more about HDF/MDF Plywood and discover the perfect fit for your interiors with Wigwam’s expert guidance.

The things that are most important to you will help you choose between engineered wood and plywood. If you want to save money and have a lot of design possibilities, engineered wood can be a smart choice. Plywood is the ideal choice, though, if you want something that will last a long time, is stronger, and is less likely to get wet. If you choose the right grade of plywood, you may construct furniture that looks nice and lasts for years.

Wigwam Ply is the best choice for plywood that is robust, elegant, and good for the environment. It’s the perfect starting point for your dream home.