Introduction

There is no question that the selection of materials that are not only sturdy but also long-lasting is of the utmost significance when it comes to the construction of modern buildings. In recent years, waterproof plywood has emerged as a popular option for use in environments that are exposed to moisture, such as bathrooms, kitchens, and exteriors. This is because waterproof plywood is resistant to water. This is because waterproof plywood is resistant to liquids, including water. Because of its ability to withstand the effects of water exposure without affecting the structural integrity of the building, it has recently become an essential component of contemporary building approaches.

Table of Contents

What Qualifies Plywood as Waterproof?

Best Use Cases: Bathrooms, Kitchens, and Exteriors

Grades of Waterproof Plywood and Their Properties

Advantages Over Traditional Wood or MDF in Wet Areas

Installation and Maintenance Tips for Longevity

What Qualifies Plywood as Waterproof

Glueing layers of wood veneers together using waterproof adhesives such as phenol-formaldehyde resin results in waterproof plywood. Waterproof plywood is produced by this method. The cornerstone for waterproof plywood manufacturing is this approach. The result of finishing this process will be plywood production. This treatment is done to make sure the plywood resists moisture passage. In the case that they do arise, this treatment helps to avoid conditions including warping, swelling, and delamination.

It is possible for termites to more effectively withstand environmental impacts, such as fungus and termites, by applying chemical treatment to waterproof plywood. Because of this, the plywood is able to better withstand the effects of these factors.

By following these processes, there is a greater possibility that the plywood will become more durable. It is possible that the application of these treatments in conjunction with the use of quality hardwood veneers could help to explain the remarkable performance of the product in moist settings.

Best Use Cases: Bathrooms, Kitchens and Exteriors

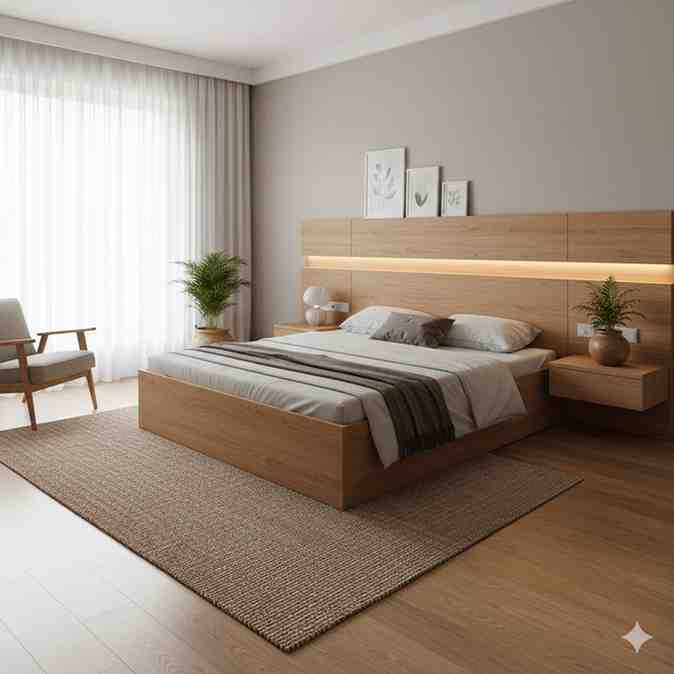

In bathrooms, where there is a high probability of water splashes and chronic dampness, waterproof plywood is an ideal alternative for the building of vanities, cabinets, and wall panels. This is because waterproof plywood is resistant to water. The construction of cabinets is a good place to look for examples of applications like this. Its moisture resistance indicates that it will require less maintenance and will continue to be valuable for a longer period of time.

When it comes to some aspects of the kitchen, such as the countertops, cabinets, and flooring, the utilisation of waterproof plywood is advantageous. Because it is resistant to stains, steam, and cleaning chemicals, the material is quite good in terms of its longevity and its capacity to maintain hygiene. Spills, steam, cleaning agents, and chemicals are all things that the material can stand up to.

Waterproof plywood can be used for a variety of exterior applications, including roofing, siding, and building furniture for the yard. It is also possible to use outdoor furniture for other purposes. Due to the fact that it is resistant to changes in temperature, humidity, and precipitation, it is guaranteed that it will keep its structural integrity and visual attractiveness throughout the course of time.

Enhance your home’s resilience with waterproof plywood solutions.

Grades of Waterproof Plywood and Their Properties

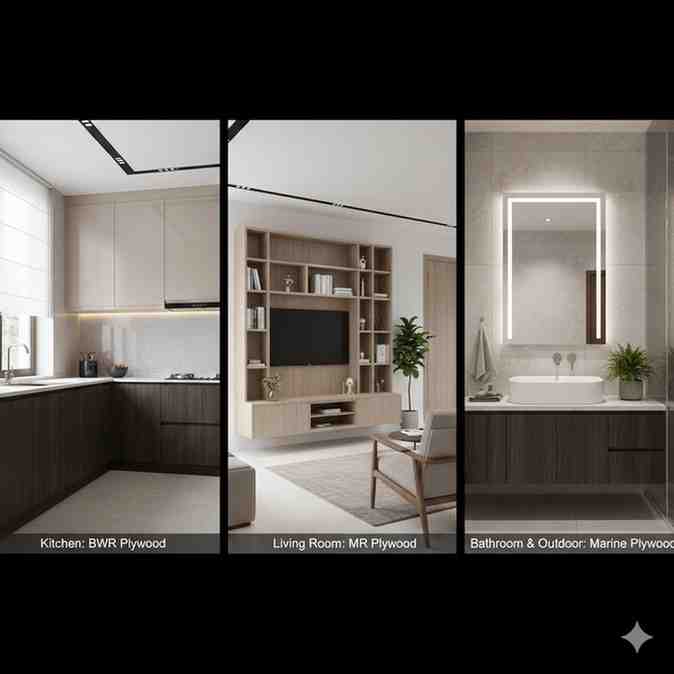

After gaining an understanding of the various grades of waterproof plywood, one is able to choose the type of plywood that is most suitable for the requirements of the tasks that are being undertaken. The MR (Moisture Resistant) Grade is the one that is appropriate for use inside, on account of the fact that there will be some moisture present throughout the day. The MR Grade does not readily absorb moisture, which is the reason why this is the case. Due to the fact that it is resistant to moisture, it does not negate the fact that every single strategy does not possess the capability of being waterproof.

In areas such as kitchens and bathrooms, where the relative amount of moisture is relatively high, Grade BWR, which is an acronym that stands for “Boiling Water Resistant”, is an excellent option to consider. The material is able to prevent delamination even after being exposed to hot water for a brief length of time.

Because it is designed to endure prolonged contact with water, marine grade, which is often referred to as BWP (Boiling Waterproof), is the highest grade. Applications in the maritime industry and projects involving the outside are two of the most common places to locate this material.

Advantages Over Traditional Wood or MDF in Wet Areas

Compared to regular wood or medium-density fibreboard (MDF), waterproof plywood has several advantages, including the following:

- Due to the fact that it maintains its structural integrity, waterproof plywood is suitable for use in moist conditions. This is in contrast to MDF, which may expand or deteriorate when exposed to water.

- The load-bearing capabilities and durability of waterproof plywood are superior to those of MDF, which ensures that it will continue to function for a longer amount of time in areas that experience a high volume of foot traffic. MDF and waterproof plywood are both capable of supporting significant weight.

- It is flexible in that it can be readily sculpted, sliced, and polished. Greater design freedom is enabled without sacrificing performance. These characteristics make waterproof plywood the perfect solution for circumstances when constant moisture worry is a factor.

Upgrade your interiors with waterproof plywood today!

Installation and Maintenance Tips for Longevity

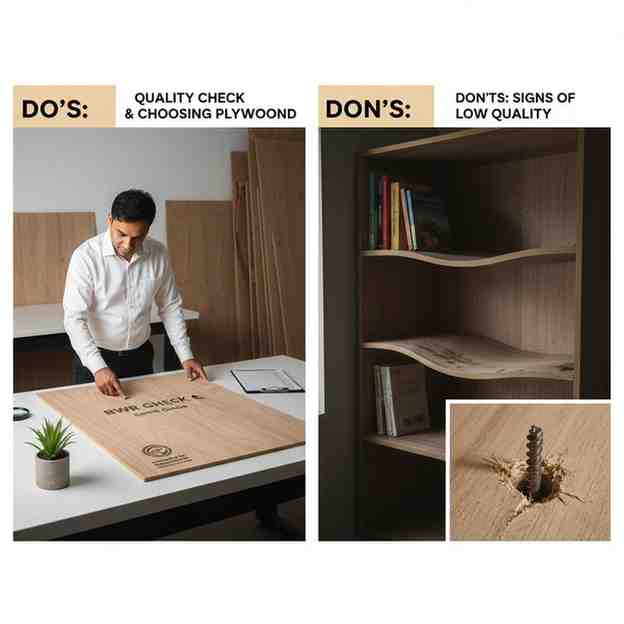

The following installation and maintenance techniques will help to guarantee that waterproof plywood has the longest lifetime possible:

- In order to prevent rainfall from penetrating the building, it is important to ensure that all of the seams and edges are adequately sealed with waterproof sealants.

- When it comes to maintaining the structural integrity of the construction over time, using screws and nails that are resistant to corrosion will be of great assistance. When conducting routine inspections, it is important to periodically examine for signs of wear, delamination, or fungal development. This is especially important in areas where there is a significant concentration of moisture.

- When cleaning plywood, it is essential to use cleaning chemicals that are gentle and focus on the surface and to avoid using an excessive amount of water. Because of this, the plywood will be able to maintain its finish and will be protected from any damage.

Following these guidelines can help waterproof plywood projects maintain their durability and aesthetically appealing look for a considerable length of time.

Conclusion

Offering exceptional durability, moisture resistance, and long-term structural integrity, waterproof plywood has changed modern buildings. From kitchens and bathrooms to outdoor decks and business interiors, its adaptability makes it a preferred choice for builders and designers who are unwilling to compromise quality. Using waterproof plywood guarantees your work withstands the elements, whether you are working on a domestic project or a major commercial build. It’s not only a wise decision, it’s a necessary one for building projects needing both lifetime and performance.

Don’t let water compromise your interiors. Shop high-performance waterproof plywood at Wigwam Ply and secure durability where it matters most.

FAQs

1. Is waterproof plywood more expensive than regular plywood?

Yes, due to additional treatments, but it offers better longevity and performance in wet conditions.

2. How do I test if plywood is waterproof?

A common method is the boiling water test, where a sample is submerged in boiling water to check for delamination.

3. How do I maintain waterproof plywood?

Regular cleaning and ensuring proper sealing during installation help maintain its durability.

4. Is waterproof plywood environmentally friendly?

Some types may contain chemicals, it’s essential to choose products certified for low emissions.

5. Can I paint or finish waterproof plywood?

Yes, it can be painted or laminated to match aesthetic requirements.