When embarking on construction or furniture-making projects, selecting the right materials can make or break the final outcome. Waterproof plywood, known for its durability and moisture resistance, is a popular choice for areas prone to dampness, such as kitchens, bathrooms, and outdoor spaces. However, not all waterproof plywood is created equal. Understanding the key factors that distinguish high-quality waterproof plywood will ensure that your project stands the test of time.

This guide will walk you through the essential steps to choose the best waterproof plywood for your needs.

What is Waterproof Plywood?

Waterproof plywood, also known as BWP (Boiling Water Proof) plywood, is a type of engineered wood designed to withstand prolonged exposure to water and moisture. It is manufactured using hardwood veneers bonded with phenolic resin, which gives it exceptional water resistance. Commonly used in both indoor and outdoor applications, waterproof plywood ensures durability in challenging environments.

Applications of Waterproof Plywood

Waterproof plywood is ideal for:

- Kitchen Cabinets: Protects against steam, spills, and dampness.

- Bathroom Furniture: Prevents swelling and warping due to humidity.

- Outdoor Furniture: Ensures durability in weather-exposed areas.

- Flooring: Provides stability and resistance to damp conditions.

- Boats and Marine Applications: Marine-grade waterproof plywood is specifically designed for high moisture and saline conditions.

Factors to Consider When Choosing Waterproof Plywood

1. Understand the Grades of Waterproof Plywood

Waterproof plywood is available in different grades, each suitable for specific applications.

- BWP (Boiling Water Proof) Grade: Best for high-moisture environments, including bathrooms and kitchens.

- Marine Plywood: Offers superior water resistance, making it suitable for boats and outdoor furniture.

- MR (Moisture Resistant) Plywood: While not entirely waterproof, it is suitable for areas with occasional dampness.

Tip: Always confirm the grade before purchasing. Look for certifications like IS:710 for marine plywood and IS:303 for MR plywood.

2. Check the Core Material

The quality of the core material determines the strength and durability of plywood. Opt for plywood with a hardwood core as it is denser and more resistant to wear and tear. Softwood cores, while lighter, are less durable and less resistant to water.

3. Examine the Bonding Process

The adhesive used to bond the veneers in waterproof plywood plays a critical role in its performance. Phenol-formaldehyde resin is the gold standard for waterproofing, ensuring that the plywood remains intact even after prolonged exposure to water. Avoid urea-based adhesives as they are less water-resistant.

4. Inspect the Finish

A smooth, even surface without gaps, knots, or uneven edges is a hallmark of high-quality plywood. Ensure that the surface is properly treated and sanded for a better finish when applying laminates, veneers, or paint.

5. Look for Certifications and Standards

Certifications indicate that the plywood meets industry standards. Look for:

- IS:710 Certification: Ensures marine-grade waterproof quality.

- CARB or E1 Certification: Confirms low formaldehyde emissions, ensuring the material is safe for indoor use.

6. Consider Thickness

Waterproof plywood is available in various thicknesses, typically ranging from 6mm to 25mm. The right thickness depends on your application:

- 6mm–12mm: Ideal for partitions and wall paneling.

- 18mm–25mm: Suitable for heavy-duty furniture and structural applications.

7. Evaluate Cost and Budget

Premium grades like marine plywood are more expensive than standard BWP or MR plywood. While the initial cost may be higher, investing in high-quality waterproof plywood ensures long-term durability and reduces maintenance expenses.

Tips for Buying Waterproof Plywood

1. Buy from Reputed Brands

Choose reliable brands known for their quality and adherence to standards. Reputed brands often provide warranties, which add an extra layer of assurance.

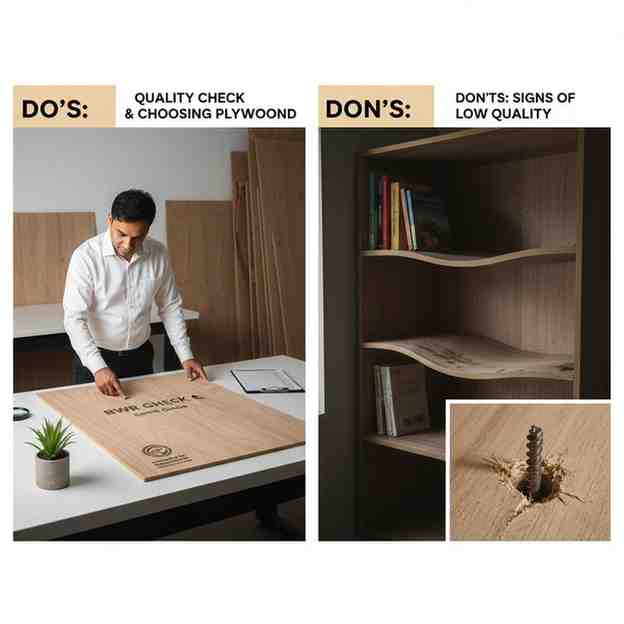

2. Verify the Product’s Authenticity

Counterfeit products are common in the plywood market. Check the branding, certification markings, and batch details to ensure authenticity.

3. Perform a Water Test

If possible, test a sample by submerging it in water for 72 hours. High-quality waterproof plywood will show no signs of swelling, delamination, or damage.

4. Seek Expert Advice

If you’re unsure about the right plywood for your project, consult a professional or a vendor with expertise in plywood and woodworking.

Mistakes to Avoid When Selecting Waterproof Plywood

- Ignoring Certifications: A lack of proper certification may indicate subpar quality.

- Choosing Based on Price Alone: Low-cost plywood often compromises on quality, resulting in long-term expenses.

- Overlooking Application Needs: Using the wrong grade of plywood can lead to failure in performance.

- Skipping the Inspection: Always inspect the plywood for uniformity, strength, and finish before buying.

Maintenance Tips for Waterproof Plywood

To ensure the longevity of your waterproof plywood:

- Apply a protective coating or laminate for added durability.

- Clean spills and stains immediately to avoid long-term damage.

- Avoid exposing even waterproof plywood to extreme weather conditions for extended periods.

Conclusion

Choosing the best waterproof plywood for your project requires careful consideration of its grade, core material, bonding, and certifications. By understanding these factors, you can ensure that your project remains durable, functional, and visually appealing.

For premium-quality waterproof plywood, Wigwam offers a wide range of options designed to meet the highest industry standards. Whether you’re working on indoor furniture or outdoor structures, Wigwam’s products combine durability with superior performance. Explore Wigwam’s collection today to find the perfect plywood for your needs!